Metal Stamping

Metal Stamping

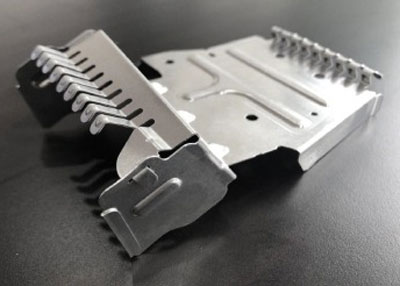

Metal stamping is a category of cold-forming process that make use of dies and stamping presses to transform sheet metal into a variety of shapes. Pieces of flat sheet metal, known as blanks, are fed into a sheet metal stamping press, which uses a tool and die surface to form the metal into a new shape. It is used to produce a wide range of components for various industries and industrial applications.

The following article provides an overview of the process, including the different metal stamping process techniques, various types of metal stamping, benefits of metal Stamping and typical industries served.

The Basics of Metal Stamping

It is a complex process that involves several complicated and intricate procedures. From the auto and aerospace industries to the medical and electronics industries, metal stamping is an integral part of producing affordable and well-crafted parts and components. Punching, blanking, bending, coining, embossing, and flanging are all stamping techniques used to shape the metal.

Common Sheet Metal Stamping Process

Metal stamping is a complex process that can include a number of metals forming processes such as punching, blanking, coining, embossing and flanging. We’ll explain the operations a little further here:

- Punching: Punching is the simplest to understand as it simply refers to the desired metal shape being punched out of the surrounding material.

- Blanking: Blanking is the most basic technique and initiates when the sheet or blank is fed into the press where the die cuts out the desired shape.

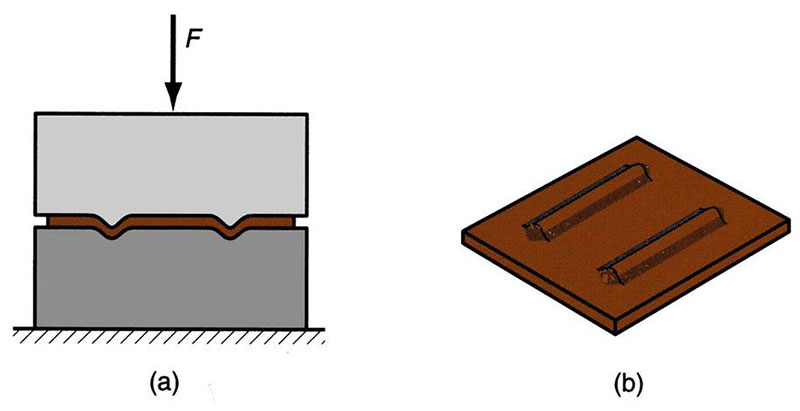

- Coining: Coining is a bending technique wherein the workpiece is stamped while placed between a die and the punch or press. This action causes the punch tip to penetrate the metal and results in accurate, repeatable bends.

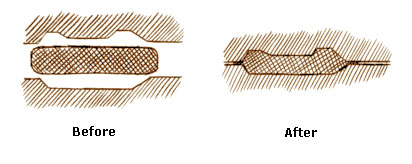

- Embossing: Embossing is a process for creating either a raised or recessed design in sheet metal, by pressing the raw blank against a die that contains the desired shape, or by passing the material blank through a roller die.

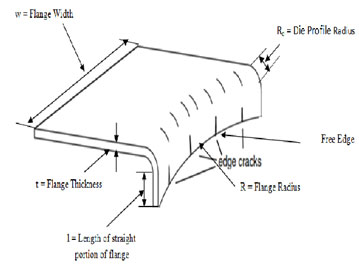

- Flanging: Flanging is a process of introducing a flare or flange onto a metal workpiece through the use of dies, presses, or specialized flanging machinery.

Types of Stamping Methods

Creative Bliss provides complete design and manufacturing for custom precision tolling. Our engineers and toolmakers will utilization of the latest techniques and processes for you based on the application specifications and cost requirements for your project. Creative Bliss provides Single Stage Process Stamping and Progressive Stamping, providing the flexibility to choose the most effective tooling.

Single Stage Process Stamping

Single stage process stamping also known as manual dies; it is a simpler process that shapes flat sheet metal to predetermined specifications in a single stage rather than multiple stages. Although single stage process stamping seems to be less efficient or productive when compared to progressive stamping, but they have their own competitive advantages. The selection of the right type of die to use for manufacturing a part becomes an important part of the manufacturing process to ensure top quality production while using the most cost-effective method.

https://www.youtube.com/watch?v=invCJ9QbkqAProgressive Stamping

Progressive die stamping is suitable for producing large amounts of parts with strict tolerance specifications. This method of stamping involves feeding a coil of metal through a stamping press, that simultaneously punches, bends, and shapes the parts.

Since it allows you to perform multiple cutting and shaping processes simultaneously, progressive stamping is suited for operations that requires a significant number of small pieces quickly. Progressive stamping can be found in a variety of industries, including automotive, locomotive, heavy trucks and RVs, electronics, and agriculture.

https://www.youtube.com/watch?v=8Lqi38Tlca4

Industries Served with Metal Stamping

Metal stamping is used to produce a variety of industrial, commercial, and consumer parts and products. Some of the industries that regularly employ the process for their manufacturing operations include:

- Aerospace

- Appliance

- Automotive

- Electronics

- Energy

- Manufacturing

- Medical Equipment

Benefits of Metal Stamping

Metal stamping is a fast and efficient method of changing the shape of sheet metal. There are even computer-controlled (CNC) stamping presses that allow manufacturers to design their desired metal shape in a computer program.

There are some of the benefits of stamping which include lower die cots, lower secondary costs, and a high level of automation. Metal stamping dies are less expensive to manufacture and maintain than those used in other common processes. Secondary costs, such as cleaning and plating, are also cheaper than for other metal fabrication processes.

Metal Stamping Services

Creative Bliss Sdn. Bhd. is based in Malaysia with the head office in Perai, Penang. It was first established in 1994. For almost 26 years, Creative Bliss operates in the Manufacturing Industry, have provided MNCs, both local and overseas, high quality metal stamping solutions and the peace of mind of working with a reliable and cost-effective partner.

When your industry requires high-caliber precision parts, you'll need a stamping company that keeps to the best quality standards. Please feel free to contact us for all your metal stamping needs.